Set screws, also known as grub screws, are a fastener used to connect an object within another object. One of the common examples is securing something to a shaft. They come in a variety of sizes and also grub screw is a term that has different meanings in the United States and the UK. This is an introductory guide about set screws, their variants, applications, and much more.

Set Screws – A simple definition

Before choosing a fastener for your build or construction, you need to know whether it is the best choice for you. Set screws are one of many solutions for connecting two materials together.

Set screws are a popular kind of fastener, with threads used for securing one object against or within another object. A simple example of such a scenario is to connect a gear or a pulley to a shaft.

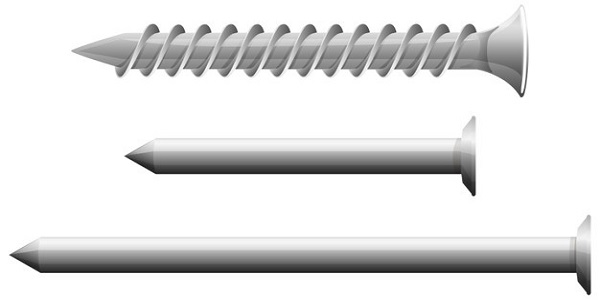

But you might ask how it differs from a bolt. Hex set screws are usually headless, unlike a bolt. Bolts with nuts, some screws in general usually have a small portion without threads. For example, a bolt has an unthreaded shank sandwiched between the head and the part that is threaded.

Application of Set Screws

Set screws can be mainly employed for mechanical and industrial devices and materials. As you saw earlier, it is used to assemble wheels and pulleys onto a shaft. They pass through threaded holes in the objects that need to be connected.

In some cases, the usage of bolts and nuts is not advised because of a few reasons. The usage of a bolt would not allow the optimal functioning of the build or maybe just will not fit into the entire device.

When two parts of the device are joined, using a bolt, the head will interfere with the proper connection with the part you are working on with another part that might come into play later in the build. This can reduce the efficiency by generating unwanted heat and other factors will also matter. Perhaps the use of nylon nuts can work, but when set screws do a much better job, you do not have to overspend.

Another factor is the appearance of the finished construction. A bolt would not hinder the aesthetic the designer originally had in mind before the assembly of the build. Heads of the Bolts sticking out will not get a suitable response for the entire build. So set screws would stay behind the veils but still perfectly do the job they were assigned.

Set screw vs Grub screw

The common mistake that most first-timers make is to think that set screws and grub screws are two entirely different things. Well, they are not. The change in names exists between the countries they are being used. For instance, workers from the USA are more prone to use the term grub screws.

Types of Set Screws

The foremost difference between grub screws from the standard bolt is that it has no head. But there are hex set screws, which, as the name suggests, have a hexagon head. Hex grub screws are known for properties like top security, non-slipping, and resistance to deformation.

Some other set screws based on head types include straight slot, square socket, external hex, external square, and Bristol spines.

Other than headed variants, set screws are available in different materials and also in varying shapes. Based on their tip shapes, these can be:

- Flat ended screws

- Cone point tip screws

- Domed point end screws

- Cup point screws

- Knurled Point screws

- Dog point screws

All these models have varying characteristics. The applications of each of these depend on whether they permanently hold on to the material, which is a property that is absent in flat-ended screws.

Some other factors include resistance to pressure and vibration, reusability, usage in both hard and soft materials, and the ability to be used at any angle. Each of the screws listed above does not have all these properties.

For example, only the oval and nylon tip set screws can be used at any angle. This function is like cladding nails made of stainless steel, which also stay hidden when fixed properly.

Apart from the division based on the type of head and tips, the material also matters.

Nylon Set Screws

These are usually used in the tips of the screws, where the aesthetics require a certain fit. Apart from the visual aspect, these ensure the material they are used on will not have any damage. A similar reason exists for the usage of plastic washers along with bolts.

Brass Screws

Brass is perfect for common domestic and hobbyist applications like fittings inside the home. The material offers low friction between moving parts, which is most fittings you use, like door locks and handles. The gold-like texture makes it perfect from an aesthetic standpoint.

Wrapping Up

From stainless steel nails to nuts and screws, the wide range of fasteners in the construction business serve different purposes, which will enhance the function and usability of the product. Set screws stand out from the rest, as they are the perfect solutions when you want the fasteners to stay hidden while performing their duties to the maximum effect.